What Food Processors Need to Know About the Future of Food Packaging

In 2025, food industry packaging is experiencing a rapid transformation. This is causing food...

Streamline operations, strengthen compliance, and hit sustainability goals — all with one partner who understands your facility.

We unify packaging, jansan, and foodservice supplies to reduce waste, cut downtime, and keep your plant compliant—with local supply and national support.

SKU rationalization, automation, and supply chain streamlining to eliminate waste and downtime.

Right-fit products across packaging, JanSan, and foodservice from trusted brands—delivered on time.

Meet EPR goals with recyclable, efficient materials that protect both product and planet.

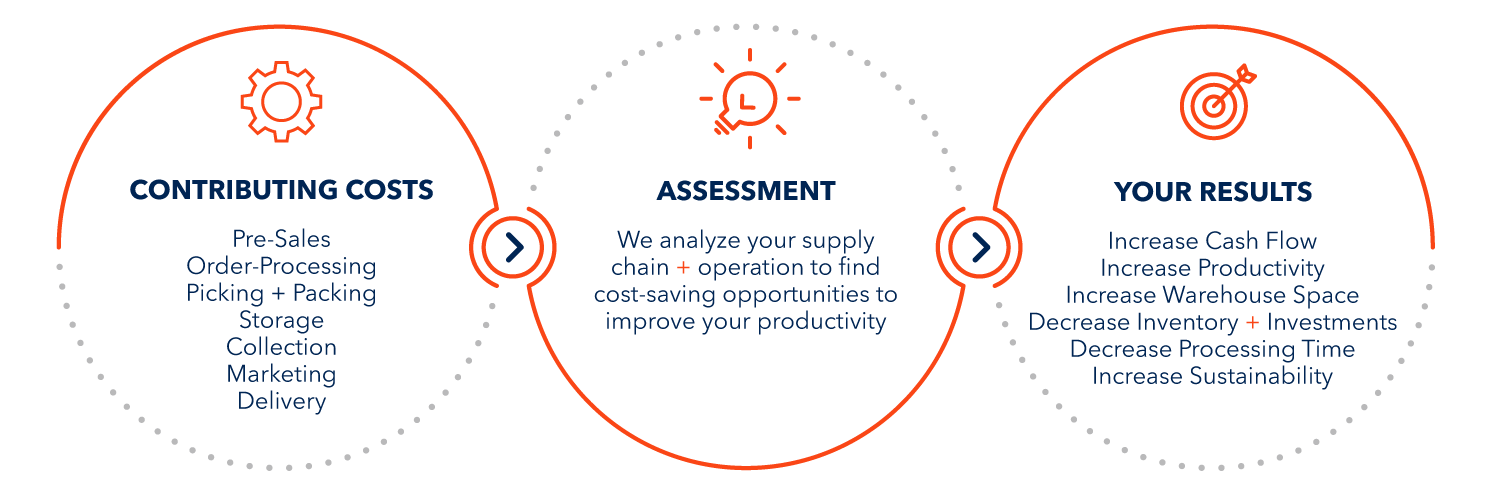

Custom Supply Chain + Efficiency Recommendations

Personalized Product Sourcing

SKU

Rationalization

24/7 Access to

E-Commerce + Support

On-time

Deliveries

Running a processing facility takes constant attention to cleanliness, safety, and compliance. We support you with JanSan products, PPE, and warewash solutions designed specifically for processors. From the right cleaning chemicals to ProWASH service and training, we help your team stay consistent and confident across every shift.

Towel + Tissues

Cleaning Chemicals

Hand Care

Can Liners

Degreasers

Brute Containers

Buckets + Mops + Brushes

Eye + Ear Protection

Gloves

Hair Nets

Beard Covers

Aprons

We offer comprehensive warewash programs designed to provide processors with consistency, quality, and safety at competitive rates. Our programs include a range of high-quality cleaning chemicals and dispensing systems, including our exclusive KleenLine™ Pro brand, and are always backed by our ProWASH expert support.

+ Pre Soaks

+ Detergents

+ Rinse Aids

+ Sanitizers

+ Dispensers

+ Equipment

ProWASH is Clean-In-Place done right: expert service, smart calibration, and cleaner performance. Less chemical waste, fewer mistakes, and consistently high sanitation standards—all backed by our on-site support team.

Formulations for proper sanitation +

residue removal

Technicians ensure quality + audit success

Solutions tailored to your facility's needs

Partnership for consistency + compliance

You need food packaging that keeps products safe and lines running smoothly. That’s exactly what we build. From proteins to prepared meals, we match you with the right films, trays, and automation to boost efficiency, cut waste, and protect your product. BradyPLUS isn’t just a supplier—we’re your productivity partner.

Polystyrene (PS) Foam

Molded Fiber

Clear Oriented Polystyrene (OPS)

Paperboard

PET and RPET

Catering

Ovenable

Microwaveable

Freezable

Tamper-evident

Multi-compartment

Hinged Lid

Aluminum

Deli

Bottles

Barrier

Co-extruded + Laminated

Standup

Reclosable

Vacuum-Sealed

Cut

Window or Vented

Shrink

Liners

Freezer

Every processor wants a smoother, more efficient end-of-line, and that is exactly what we help you build. We assess each part of your workflow from containment to palletizing and recommend packaging, equipment, and automation that improve speed and reduce downtime. Pair that with vendor-managed inventory and ongoing service, and you have a partner fully aligned with your operational goals.

Barrier

Co-extruded + Laminated

Forming + Non-forming

Overwrap

Lidding

Shrink

Bundling

Stretch

Pallet Covers + Liners

Pan Liners

Overwrap

Interleaving Sheets

Labeling Systems

High-Speed Closers

De-Nesters

Conveyors

Pallet Wraps

Strapping

Tape

Adhesive

From containment to pallet stabilization, our end-of-line experts help processors reduce waste, downtime, and labor costs with smarter packaging design, automation, and supply integration.

Line and waste assessment to identify efficiency gaps

Right-fit materials, films, corrugated, and equipment

Install, train, and optimize your systems

VMI programs, equipment service, and data insights that keep performance high

BradyPLUS helps processors reduce waste, meet EPR goals, and protect product integrity with smarter materials and data-driven packaging optimization. We improve recyclability, right-size your packaging, and lower carbon impact while keeping production strong.

Reduce excess material and eliminate overpack with packaging that fits your product and line requirements. We help you streamline formats and gauges for better efficiency and lower waste.

Move toward more recyclable materials without compromising performance, safety, or throughput. Our team helps you choose substrates and redesign components to support circularity.

Lower your footprint with materials and designs proven to reduce carbon impact while keeping production strong. We use testing and analysis to help you make confident, measurable improvements.

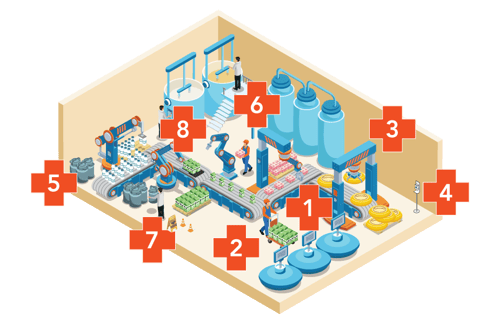

Essential 8 is our facility assessment tool that helps processors pinpoint opportunities to improve cleanliness, safety, workflow, and cost efficiency. We walk your plant, evaluate eight core operational areas, and give you a clear roadmap to strengthen performance across your entire facility.

Explore our latest insights, tips, and updates on all things BradyPLUS!

In 2025, food industry packaging is experiencing a rapid transformation. This is causing food...

Food-related illnesses are on the rise, with pathogens lurking in floor drains, ventilation...

When it comes to food processing—cleanliness is always top of mind. For food processors, there are...